*Warranty Return Procedure*

Samlin compressors are subject to failure if the proper system conditions are not maintained. Below is a list of some common compressor failure modes caused by external factors and are not a responsibility of Sanden's quality or workmanship.

CENTERBALL SEIZURE

The centerball (also known as the centering ball) functions as a pivot point between the pivoting planet plate assembly and the stationary fixed gear. As the compressor shaft rotates, the planet plate swivels / pivots around the fixed gear. The centering ball allows the planet plate to pivot up and down as the shaft rotates. This up and down movement of the planet plate allows the pistons to move up and down in the cylinders.

During normal compressor operation, the centering ball is coated with an oil film which reduces friction and allows for the dissipation of heat. The system refrigerant acts as a heat carrier and aids in the lubrication of and removal of heat from the centerball. Centerball Seizure is a catastrophic condition which results when the compressor and / or centerball is deprived of adequate lubrication and cooling. As the lubrication and / or refrigerant are depleted the friction and temperature of the parts increase rapidly until thermal distortion and parts failure occurs. This failure usually results in the centerball melting and becoming welded to the fixed gear.

Centerball seizure occurs as a result of lack of lubrication and cooling around the centerball. This condition can be caused by the following:

A) TXV blockage or Malfunction.

B) Thermostat failure.

C) No air flow to Evaporator ( Blower fan motor failure

D) Lack of refrigerant and I or oil due to a leak.

E) Lack of return oil due to too long a circuit or system undercharge.

F) Lack of refrigerant flow due to inadequate charge.

G) Blockage in system due to Contamination in system.

H) Defective centerball or gear mating surface.

I) Liquid slugging due to improper system charging.

J) Charging Liquid refrigerant into compressor (washes off oil film from around centerball).

There are 4 primary categories of centerball seizure.

1. Partial Seizure = A partial seizure occurs when the centerball slightly deforms and loosely welds to and then separates from the fixed gear. The shaft may still rotate but the rotation will be rough and often above normal torque requirements.

2. Typical Seizure = A typical seizure occurs when the centerball overheats and completely welds to the fixed gear. This results in zero rotation of the compressor shaft and may often lead to clutch failure as a result of non rotation of the shaft.

3. Meltdown = A meltdown occurs when the overheating is severe enough and prolonged enough to cause complete melting and deformation of the center ball. This condition may also result in both zero rotation of the compressor shaft and possible clutch failure as a result of non rotation of the shaft.

4. Clean Seizure = A clean seizure results when the centerball failure occurs rapidly and with minimal damage to surrounding parts. In most cases the seizure occurs within a few hours of initial compressor engagement. The compressor oil is often clean and free of contamination. There is usually very little evidence of overheating in these cases. Clean seizures are usually the result of assembly and / or material defects or improper system charging.

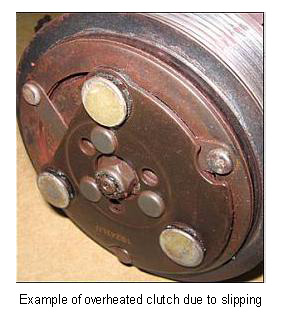

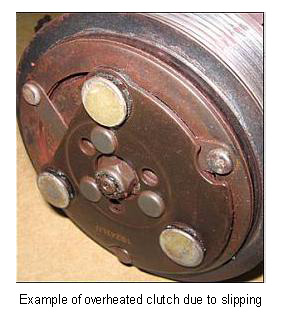

CLUTCH SLIPPING

Clutch Slipping is a condition that occurs when the armature plate fails to engage and rotate in synchronization with the clutch rotor. The field coil when energized becomes an electromagnet which then magnetizes the Clutch rotor and Armature plate. Friction and magnetic attraction cause the Armature plate and Clutch rotor to lock together (clutch engagement) and rotate the compressor shaft.

Clutch Slipping specifically refers to a situation that occurs when the armature plate fails to lock together properly with the rotor. The armature will then tend to drag (slip) against the rotor surface. This dragging (slipping) results in intense friction and heat. As the slipping continues, the heat causes deformation of the armature plate. In the case of a rubber armature, clutch slipping may lead to melting of the rubber damper and can result in a subsequent failure of the entire clutch mechanism.

Possible Causes of Clutch Slipping and overheating: Liquid slugging -will cause high shaft rotation torque. This inhibits rotation of the armature plate and leads to slipping. Contamination on friction surfaces - will diminish the coefficient of friction between the two mating surfaces and result in slipping of the armature. Low voltage to the field coil - causes a reduction in the strength of the magnetic field of the field coil. System overpressure - will cause high shaft rotation torque. This inhibits rotation of the armature plate and leads to slipping. Engine harness defective connection - may result in insufficient current being applied to the field coil.

CUSTOMER DAMAGE

Customer damage refers to instances where compressor failure is caused by improper installation, mishandling and / or incorrect system application.

Compressors are susceptible to damage whenever failures occur within the A/C system. System failsafes such as Pressure Relief Valves (PRV), Thermal Protection Switches (TPS) and High / Low pressure cut offs are often used to reduce the possibility of compressor damage under abnormal system conditions. These devices limit damage to A/C components by making the system inoperable whenever a severely abnormal condition develops.

When a returned compressor is analyzed for failure responsibility, the physical condition of the compressor is examined to determine if the compressor was subjected to handling damage and / or improper installation. If the compressor has external indications, or shows evidence that it was subjected to extreme conditions which caused the failure, then the cause of the failure may be determined to be customer damage.

Broken port due to over-torque Customer damage includes but is not limited to the following:

A) Overtorquing of mounting bolts which may break compressor ear mounts.

B) Overtorquing of hose fittings which can result in stripped threads or broken ports.

C) Improper field service. Parts that are incorrectly replaced or installed can result in subsequent compressor failure.

D) Mechanical damage to the clutch, scratches, nicks, dents, air gap modified, lead wires pulled out, pinched, cut etc.

E) Mechanical damage to the compressor cylinder block.

F) The addition of non approved chemicals which may cause system and / or compressor malfunction.

G) Improper packaging or handling of the compressor.

H) Improper modification of the compressor i.e. painting, plating, polishing etc.

Moisture Contamination

Rusted valve components due to moisture in system

MOISTURE CONTAMINATION

Moisture Contamination refers to a failure which results from conditions which can occur when moisture is introduced into the A/C system.

The A/C compressor is designed to perform efficiently under specific controlled conditions. if contaminants are introduced into the system they act to reduce compressor efficiency, effectiveness and durability Moisture as used in this text refers to water in any form ( solid, liquid or gas).

When moisture is introduced in the A/C system, it may combine with the system refrigerant to form an acidic solution which can erode internal compressor components. In this case moisture does not cause direct compressor failure; the failure results from the failure of a part which has been weakened as a result of the effects of rust and/or corros During normal compressor operation, the pistons compress refrigerant gas in the cylinders.

Moisture in the system can lead to liquid slugging. Liquid slugging is a condition which occurs when liquid is allowed to enter one or more cylinders.

Because liquid is practically non-compressible, the compressor seals may be compromised when the pistons attempt to compress the liquid. Liquid slugging can lead to permanent valve damage and reduced compressor efficiency.Copper plating is a condition in which metal parts in the compressor become coated / plated with copper. This condition is often observed in compressors which have a high moisture content in the A/C system.

One possible cause of copper plating is that as moisture (water) combines with the refrigerant, it forms an acidic solution; this chemical may then dissolve or leach copper from other components in the A/C system which are copper or contain copper-based alloys such as brass or bronze. The method by which the copper is deposited on metallic parts of the compressor (i.e. Races, Bearings, Centering ball, Fixed gear etc) is not known for certain, but this occurrence would have to be facilitated by the circulation of refrigerant, oil and moisture in the A/C system. Although copper plating alone does not cause a specific failure of the compressor, the conditions under which it is likely to occur are very detrimental to compressor durability.

Moisture Contamination occurs as a result of moisture being allowed to enter and remain in the A/C System.

This condition can be caused by the following:

A) System leaks.

B) Improper Vacuuming of system.

C) Contaminated system components.

D) Contaminated refrigerant and / or oil.

E) Saturated or malfunctioning drier.

There are 4 primary identifiers of moisture contamination.

1. Copper Plating = The presence of copper plating generally occurs when there is a high moisture content in the A/C system.

2. Rust = Rust may occur on internal steel compressor components that are exposed to moisture for extended periods.

3. Slugged Valves = A Slugged valve is one that has been permanently deformed as a result of liquid slugging.

4. Contaminated Oil = Contaminated oil reflects a contaminated system.